Reading time

4 Minutes

Published

Additive Manufacturing for Serial Production: Insights from CalBench X

Additive Manufacturing (AM) has revolutionized product development by enabling rapid prototyping, reducing design iteration cycles, and minimizing risks. However, many companies struggle to integrate AM effectively into serial production. IMT's development of the CalBench X provides a compelling case study demonstrating how AM can be leveraged beyond prototyping to enhance ergonomics, function integration, and customization in production environments.

Insight in Brief

This article deals with the following topics:

- Ergonomics: Additive manufacturing enables complex, lightweight geometries that improve usability and accessibility.

- Function Integration: The design freedom of Additive manufacturing allows multiple functions to be embedded into single components.

- Cross-Compatibility: Additive manufacturing bridges compatibility gaps between different systems through easily produced adapter parts.

- Rapid Modification: Additive manufacturing facilitates cost-effective and rapid design modifications without requiring expensive retooling.

- Customization: Additive manufacturing allows for tailored parts with minimal additional complexity.

Introduction

Additive Manufacturing offers many benefits that IMT is very successfully implementing in its design and development process. Faster prototyping-to-production transitions and easier design iterations reduce risks and enhance product development with 3D printing.

With prodartis AG as a capable partner, IMT can fully leverage the advantages of additive manufacturing. This collaboration allows for optimized processes and enhanced integration of AM technologies throughout various phases of production.

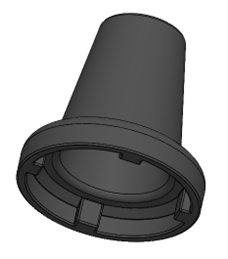

Apart from rapid prototyping during development, AM also offers many compelling advantages that makes it interesting for serial production. It offers reduced lead times by eliminating tooling requirements, thus enabling faster market entry. It is cost-effective for small to medium batches by avoiding high upfront investments in molds. Decentralized manufacturing allows on-demand, localized production, reducing logistics costs. The process enhances material efficiency and sustainability by minimizing waste due to lightweight structures that optimize material use and functionality. For another example, read our Expert Blog article on using generative design to optimize a blower coupler for a lung simulator.

Despite these benefits, many companies still struggle to successfully integrate additively-manufactured parts into serial production. CalBench X is a calibration-bench for gas flow meters developed by IMT and acts as compelling case-study of how AM parts can be used in a low-volume serial production device.

CalBench X relies heavily on parts produced by additive manufacturing and shows how its unique benefits can be leveraged not only in the development of devices, but also in serial production units.

The project brief for the CalBench X demanded for a physical design that is reliable, robust, ergonomic to use and easy to maintain. The goal of this article therefore is to provide concrete examples of how additively manufactured parts have been implemented for improved results in these areas.

Ergonomics

Unlike traditional manufacturing methods, 3D printing allows for highly complex geometries and intricate designs without additional costs. This made some of the special parts possible, which are needed for the improved ergonomics of the calibration-bench. One example are the slider housings, these position the inlet pipes to perfectly match up with the corresponding connections on the devices which should be calibrated. These housings can also be shifted into different positions, the shape of the housing makes it clear and comfortable where they can be held to do so.

Also relevant for usability and ergonomics are the position of the filters on the flow channels. These need to be changed regularly so they need to be easily accessible. Having them recessed into custom AM-Inserts in the tabletop allows for easy access when they need to be changed while they are still out of the way in everyday use of the bench.

Having the attachments of these filters recessed into the tabletop comes with the new challenge of not being able to reach the special mounting hardware for the tubing system. Luckily, an appropriate tool could be easily manufactured using AM as well and can be supplied with each CalBench X.

Functional integration

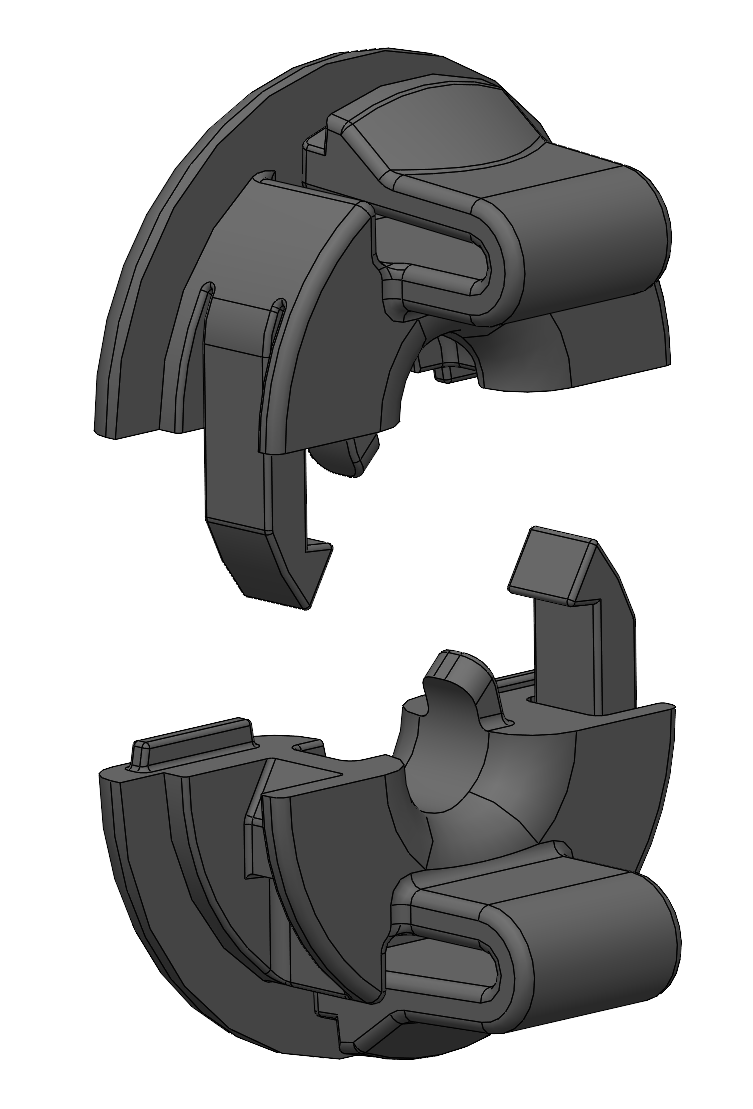

The design flexibility of AM not only allows for parts that are ergonomic. The design freedom that comes with AM can be used to integrate many functions in a single part. One great example where this has been achieved is the Bearing Block of the CalBench X. This part is hidden in the slider housing. It is rigidly mounted to the tabletop. A special bearing is snapped in an holds the inlet pipe for High-Flow, which can be both rotated and moved axially in the bearing. A pin that screws into the holder block and through the bearing limits these movements of the inlet pipe. Further, there are two spring-loaded metal balls pressed into the base of the holder. These snap into the slider housing when it is moved to its extreme positions, providing haptic feedback to the operator.

The bearing-holder also gives a great example of some of the ways functions can be integrated into AM parts:

- Snap hooks for easy and toolless assembly with the option of disassembly for maintenance or repairs

- Threads integrated directly into the plastic part provide simple and efficient connections for non-critical screw connections

- Inlaid nuts ensure a strong and secure threaded connection with high load-bearing capacity

- Pressed-in parts for easy assembly of parts which do not need to be disassembled

Enabling cross-compatibility of different systems

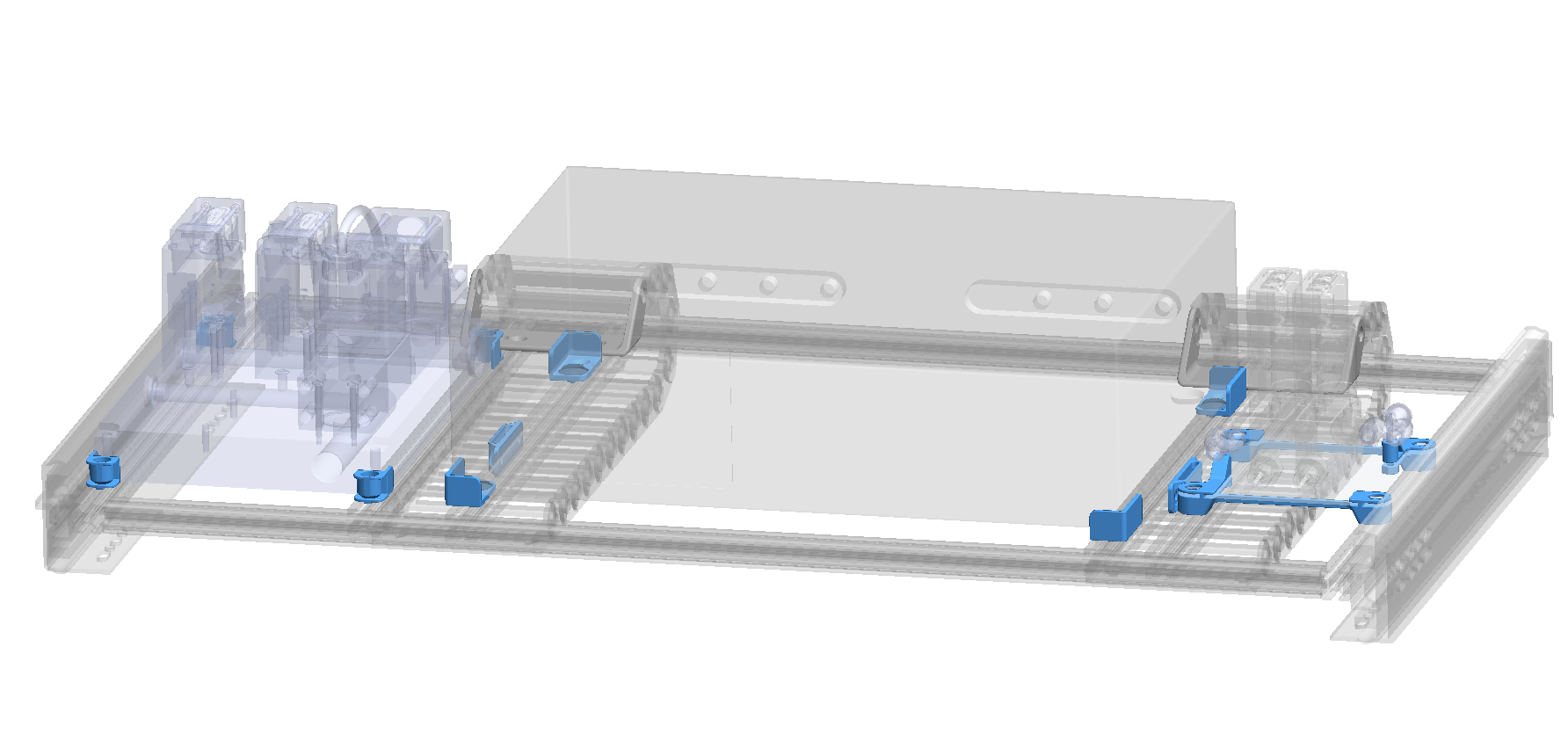

The main frame of the CalBench X is built from a profile system. These systems offer many options to connect different parts and mount hardware. However, there always exist corner cases for which no appropriate mounting solution is available. Here AM can bridge the gap by offering an easy way of producing adapter parts that ensure cross-compatibility of different systems.

Here are some examples:

- Top hat rail to hole pattern of pneumatic components: The printed adapters allow to mount various pneumatic parts to a standard top hat rail. Different configurations of the model allow to quickly adjust the part to the different hole patterns of the various pneumatic components. The snap fit on the holder ensures that the components can be easily attached and detached, without needing any tools. Additionally, the scaffold-like design minimizes material use, resulting in an economical and lightweight part.

- Panel-mount adapter for pressure gauges, where no standard parts were available.

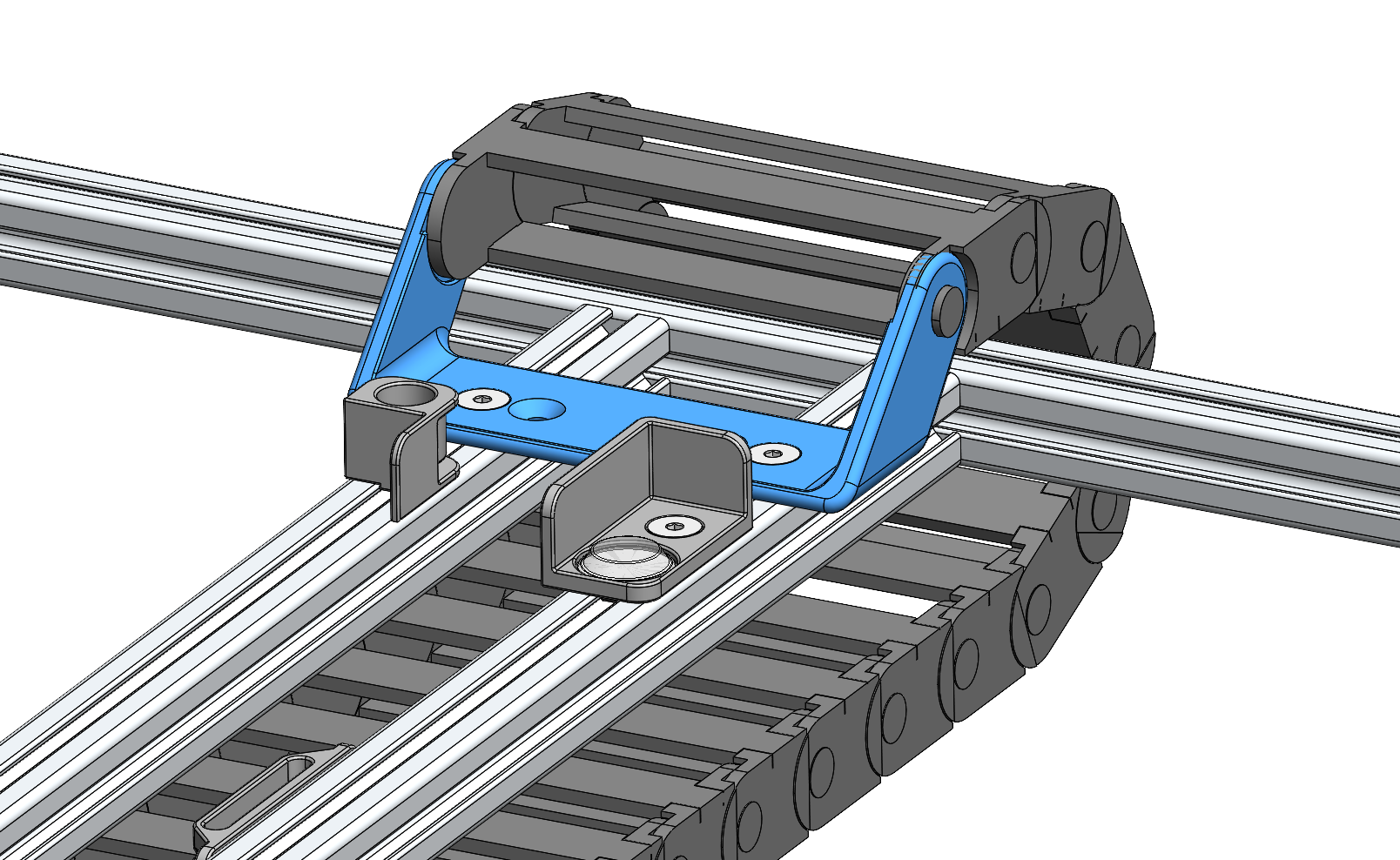

- Cable drag chain to profile system

- Mounting brackets to locate removable components on profile system

Rapid design modification without retooling

Some purchased parts will become obsolete during the lifetime of the CalBench X. This happened e.g. for the bubble humidifier mounted to the side of the calibration-bench. The shape and dimensions of the replacement part vary from the original bubble humidifier significantly, making a redesign of its holder necessary. Since the holder has been manufactured by AM, these design modifications could be implemented without expensive retooling.

Customization

AM allows for customization of parts with minimal added complexity. This can be leveraged e.g. when adding labels to parts to keep things organized. The CalBench X contains a lot of pneumatic tubing. Having these tubes appropriately labelled improves assembly and future maintenance.

Cable entries could be customized to fit the pneumatic tubing in an optimal way, ensuring a good fit and smooth operation.

Putting it all together

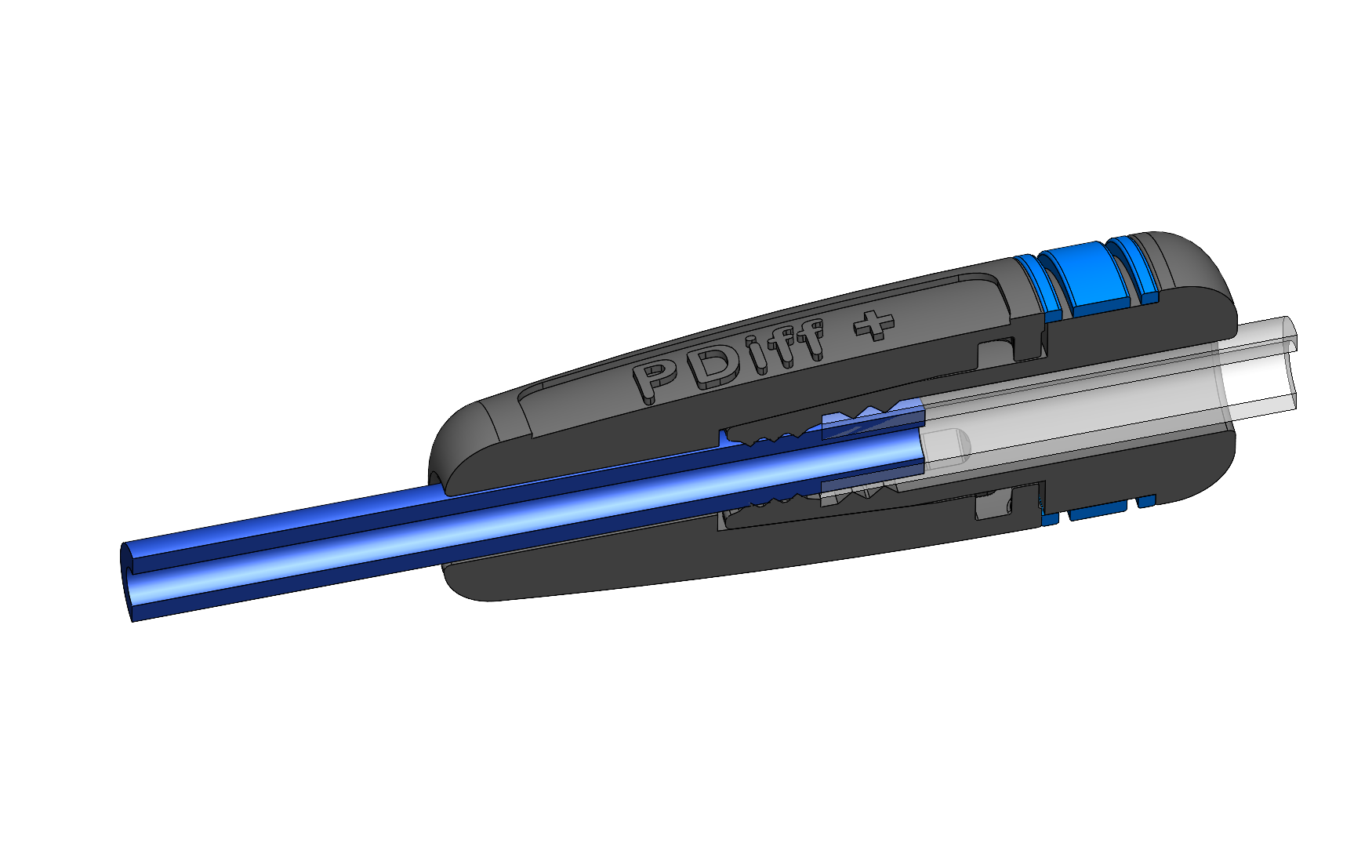

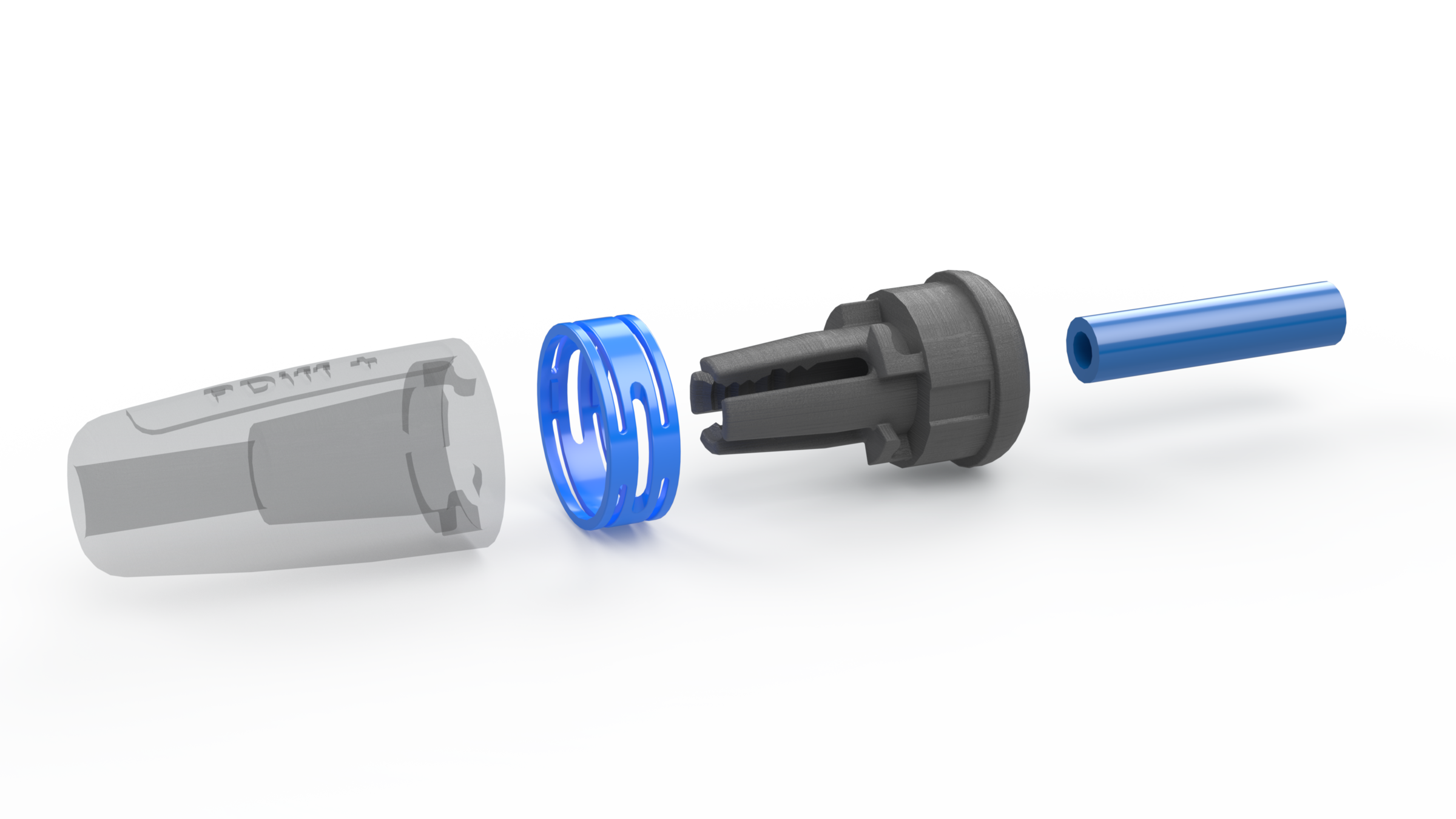

The CalBench X contains many AM parts that leverage the benefits of AM in a serial production device. These benefits can be summarized in a single part of the CalBench X: the label cuffs. These parts improve ergonomics by providing a grip on the pneumatic tubes that need to be connected to the pneumatic nipples on the devices to be calibrated. Function integration is achieved by the two-part design which is snapped together: it allows to integrate a colored ring for color coding of the connectors while also acting as clamp which secures the two tubes relative to each other. In doing so, it offers cross-compatibility of the standard-pneumatic tube and the flexible silicone tube. The part has already seen rapid design modifications since the diameter for the connecting tube needed to be adjusted for the vacuum port after some tightness issues surfaced in early tests. Finally, each of the cuffs is customized with appropriate labeling to provide additional guidance to the color coding of the lines.

Conclusion

IMT’s CalBench X shows how additive manufacturing can be integrated into serial production. The project demonstrates how AM enhances ergonomics through features that provide clear, intuitive handling and improve accessibility. Function integration within CalBench X highlights how AM simplifies assembly and reduces part count while improving overall functionality.

The ability to make rapid design modifications without the need for retooling demonstrates AM’s capacity to adapt quickly to changing requirements. Customization through integrated labelling and color-coding improves identification and operational efficiency. By leveraging these benefits, IMT has successfully integrated AM into a serial production environment, reducing lead times and increasing design flexibility.

More Expert Blog articles

Discover IMT’s engineering expertise and innovative solutions in our Expert Blog. Gain valuable know-how from our experts and explore technology highlights.