Reading time

15 Minutes

Published

IMT’s 2025 Innovation Report

Download Report

Click here to download our IMT Innovation Report 2025 as a PDF.

Content

- 01 Management Foreword: Accelerating Innovations

- 02 Innovation Workshops: Problem Solving with Design Thinking

- 03 Product Design: Combining Functional Innovation with Aesthetics

- 04 Rapid Prototyping: Accelerating Innovations in Mechanics and Electronics

- 05 Simulations: Predicting Innovation's Performance in silico

- 06 Generative Design: Leveraging AI to create Innovative Designs

- 07 Pneumatics Engineering: Enabling Innovation with Modular Toolbox

- 08 Embedded Systems: Empowering Innovative Designs with DATAFLOW

- 09 Innovative Lung Simulator: Breakthrough with alveo

- 10 IMT Academy: Preparing Your Talent to Drive Innovation

Management Foreword

Welcome to the first edition of IMT Innovation Report. As our R&D expertise grows year by year, we want to share how we can accelerate your innovation journey through new technologies, processes and tools.

As an engineering company, IMT strives to offer state-of-the-art services to enable creation of innovative solutions. A few years ago, a technical advisory board was established - a group of technical experts that ensures IMT stays ahead of trends and integrates promising R&D technologies into operations. Since then, we have significantly broadened our service offering as well as expanding our competencies and technical infrastructure.

For example, embracing design thinking methodologies, our experts conduct innovation workshops that spark creativity, uncover unmet needs and align teams. We have established our in-house product design expertise, including UX/UI and industrial design capabilities. To support agile development, rapid prototyping is enhanced with 3D printing and in-house PCB electronics assembly. ANSYS and other tools are used early in projects for in-silico simulation of mechanical, thermal, and fluid behaviors.

With generative design, our experts leverage AI to optimize mechanical components. For pneumatic projects, IMT developed a modular toolbox to speed up the development. In software, we accelerate embedded systems development with our IMT DATAFLOW tool suite and IMT Base code library.

A key project that unites many of these technologies is alveo, an innovative lung simulator. Launching in late 2025, alveo features multiple innovations in performance, design, and functionality. We believe that innovation depends on knowledge and talent. That’s why in 2023 IMT Academy was launched. It offers training on topics like usability, cybersecurity, software development, market access and more.

At IMT, innovation is all about making ideas work. Whether in software, hardware, AI, or system integration, we’re here to support and accelerate your innovation journey. Enjoy reading our report!

Christian Büchel, CEO & Harri Friberg, Managing Director

Innovation Workshops

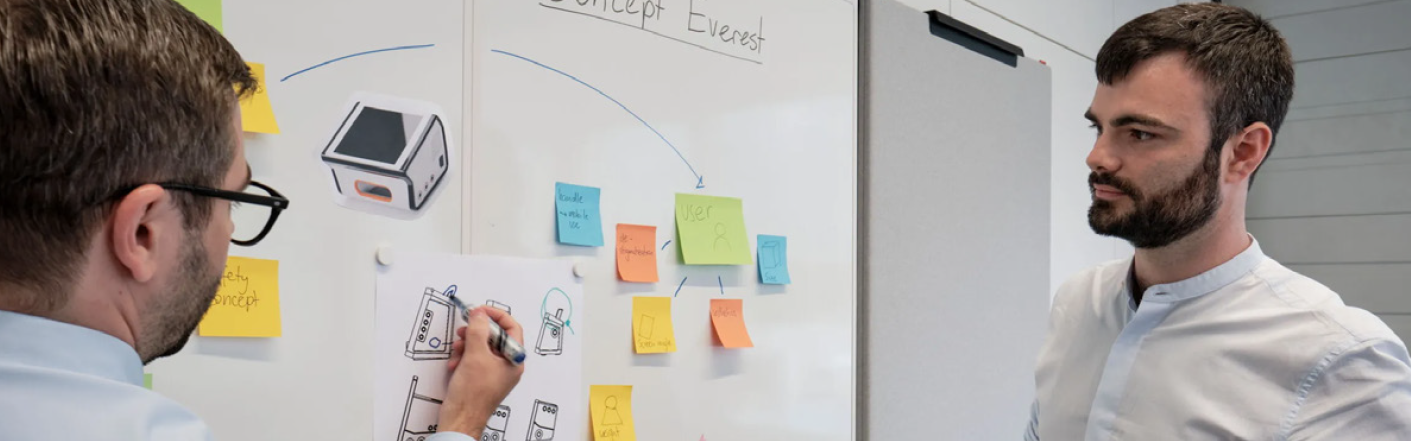

Staying ahead in today’s market means adapting to customer needs, emerging technologies, and increasing competition. IMT’s design thinking workshops provide a structured, user-centric approach to solving complex challenges, fostering creativity, and aligning teams around impactful solutions.

Our innovation workshops follow the double diamond model, guiding teams from problem identification to actionable solutions. Participants analyze challenges, define problems, brainstorm solutions, and prototype concepts. The double diamond process begins with the Discover phase, where teams identify challenges, gather insights, and understand user needs.

In the Define phase, these insights are refined into clear problem statements. During the Develop phase, participants brainstorm and explore innovative solutions. Finally, in the Deliver phase, prototypes are created, tested, and refined to ensure they are ready for implementation.

By focusing on empathy with customer environment, problems and needs, rapid prototyping, and iterative testing, we help uncover pain points and develop market-ready innovations. Whether launching a new product, optimizing an existing one, or identifying growth opportunities, our workshops turn ideas into tangible results.

Beyond ideation, we support implementation, ensuring strategies are effectively executed. Product managers, CEOs, and R&D leaders leave with clear insights, validated prototypes, and a roadmap to innovation success.

Product Design

Turning a technical solution into a successful product means working with a User Experience in mind. Product design is the key — at IMT, we ensure that a holistic and coherent approach is taken.

In 2024, we launched our in-house product design team, marking a significant milestone in the expansion of our innovation capabilities. This move reflects our deep commitment to delivering high-quality, human-centered design solutions tailored to our clients’ specific needs.

Our product design expertise unites product, user experience (UX), and user interface (UI) design into a seamless workflow — guiding ideas from early concept to a finished, market-ready product. Our approach blends user-centered design principles with deep technical knowledge to create solutions that are both functionally robust and visually compelling.

In medical settings, our designs play a critical role in enhancing patient safety and improving the quality of care. We follow the IEC 62366 standard to define usability specifications and conduct usability evaluations throughout development, ensuring compliance with regulatory requirements and optimal user interaction.

Our UX/UI design practice focuses on building intuitive, aesthetically refined, and accessible interfaces that resonate with users and eliminate barriers. By using a Figma-to-code toolchain, we streamline the transition from design to implementation, accelerating development cycles without compromising quality.

Whether designing intricate medical devices or next-generation high-tech systems, IMT’s design team collaborates closely with clients to ensure their vision is realized — while meeting the highest standards of safety, usability, and innovation.

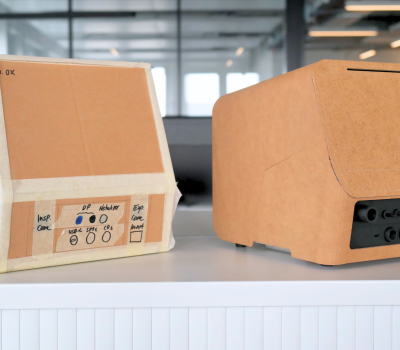

Rapid Prototyping

To accelerate product development, IMT has significantly expanded its rapid prototyping capabilities in mechanics and electronics. This enables faster iterations, reduces risks, and supports the "fail fast, fail early" principle — essential in innovation.

Prototyping shortens the path from idea to physical model, allowing engineers to quickly validate designs. By catching errors early, it delivers cost savings and better outcomes.

In mechanics, we use CNC machining and various in-house 3D printing technologies to create precise, functional prototypes. Depending on requirements, we apply:

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

For example, SLS is ideal when prototypes require uniform mechanical properties and a visually consistent surface.

In electronics, our in-house PCB assembly eliminates dependency on external suppliers, enabling faster turnaround and greater flexibility. As soon as a PCB design is finalized, we don’t have to wait for a timeslot at an external electronic manufacturing partner. With computer-aided assembly, precise solder paste application, and automated soldering, we produce high-quality PCB prototypes in minimal time. It also enables faster iteration cycles and enhanced responsiveness to design input changes.

Supported by our in-house simulation and testing lab, mechanical and electronic prototyping approach enables faster, more informed development with fewer iterations and lower costs.

The result: shorter development cycles, higher quality, and the flexibility to adapt to changing requirements. IMT’s rapid prototyping empowers clients to innovate with confidence — turning complex ideas into market-ready solutions.

Simulations

In recent years, IMT has strategically invested in simulation expertise, expanding our capabilities with advanced tools and know-how to better support clients in developing reliable, high-performance products.

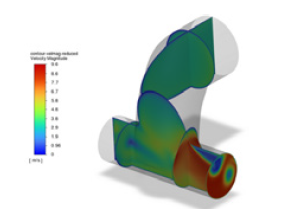

Simulation is a cornerstone of our engineering process — enabling faster development, lower costs, and smarter decision-making. Our expertise spans Computational Fluid Dynamics (CFD), thermal simulations, and Structural Mechanics using the Finite Element Method (FEM). These tools help visualize and validate complex physical behavior before a single prototype is built.

Using platforms like ANSYS Fluent, ANSYS Mechanical, and SolidWorks Flow Simulation, we simulate airflow, heat transfer, and mechanical stress in systems such as ventilators and high-tech components. This allows us to optimize complex systems, ensuring efficiency, durability, and lightweight design while meeting performance requirements. By integrating simulation-driven design, we reduce reliance on costly physical prototypes — enabling faster iterations, improved accuracy, and early issue detection.

Structural simulations go beyond basic stress analysis. We evaluate material behavior under load, predict failure points, and simulate real-world environmental conditions. Combined with physical testing, this accelerates development and boosts confidence in critical design decisions.

CFD simulations reveal hidden phenomena such as pressure drops and vortex formation, while thermal simulations guide cooling system design. These insights enhance performance, safety, and energy efficiency.

For our clients, simulation means faster cycles, fewer errors, and more successful prototypes — transforming invisible risks into clear insights and driving innovation forward.

Generative Design

Generative design is transforming product development by merging computational intelligence with engineering creativity. At IMT, we harness this powerful approach to create optimized mechanical designs that meet strict requirements for performance, material efficiency, and manufacturability.

Unlike traditional design methods, generative design explores a vast range of possible solutions based on user-defined goals and constraints such as airflow, strength, weight, material usage, and thermal performance. Using algorithms, AI, and advanced simulations, we automatically generate and evaluate hundreds of design variations — selecting those that offer the best balance of form and function.

IMT integrates generative design into the development of complex, high-performance components, particularly where conventional methods fall short. A standout example is the blower coupler optimization for a lung simulator, where our team reduced pressure differential by 13% while significantly minimizing material consumption. This was achieved through a hybrid process combining generative design, simulation, and additive manufacturing.

We employ tools like Fusion 360, ANSYS Fluent, and Adjoint Solver to simulate fluid dynamics and structural behavior across different geometries. The result: organic forms and lattice structures that maximize airflow, reduce weight, and improve strength — unlocking design possibilities that traditional CAD can't offer.

By combining classical engineering, generative algorithms, and in-house 3D printing capabilities, IMT delivers designs that are not only smarter and lighter, but also more sustainable and ready for real-world production. This innovation-first mindset allows our clients to stay ahead — with components that perform better, weigh less, and are built faster.

Pneumatics Engineering

The innovation in pneumatic devices demands not only precision but also agility and speed. At IMT, we reimagined this process by creating a modular pneumatics toolbox — a solution designed to streamline and accelerate the development of innovative solutions.

Our goal was clear: reduce development time, simplify setup and testing, and make it easier to validate new ideas early in the process. The toolbox delivers on all fronts, enabling fast prototyping and concept evaluation without compromising on quality.

At the heart of this innovation is modularity. The toolbox includes pre-engineered, customizable components such as a turbine-, valve-, voltage controller-, pump-, stepper motor-, and sensor-modules.

These building blocks allow developers to quickly assemble and adapt complex pneumatic systems, accelerating development cycles and reducing engineering overhead. The toolbox is easy to use, even with minimal programming knowledge. Thanks to 3D printing, the mechanical connection in test setups - housing, cover elements and brackets can be easily customized.

The adaptability is a key advantage. Whether for respiratory devices or precision fluid handling systems, the toolbox supports a wide range of applications — empowering teams to focus on innovation. Additional modules, extensions and customized software can be developed at the customer's request.

Regularly used in IMT’s own development projects, the toolbox enables early testing of pneumatic concepts. Additionally, insights from its electronic design have been applied to client projects, delivering added value beyond our internal use. This initiative reflects IMT’s commitment to delivering innovative solutions in pneumatic engineering.

Embedded Systems

The core of IMT’s expertise lies in the development of embedded systems. Over the years, countless engineering projects have prompted us to launch an internal innovation initiative aimed at streamlining embedded software development across complex device architectures. This initiative led to the creation of IMT DATAFLOW.

Built on decades of software development experience, IMT DATAFLOW is a proprietary framework that enables efficient, high-performance, and resourceoptimized embedded development. It standardizes workflows, enhances traceability, and fosters seamless collaboration between engineering disciplines — reducing risk, improving maintainability, and accelerating time-to-market.

To support this framework, we developed two innovative tools:

- DATAFLOW Runtime: an event-based runtime engine that simplifies application logic on the target system.

- DATAFLOW Designer: a visual, event-based design tool for embedded system architecture, offering a systematic approach to planning, development, and automatic code generation.

Together, these tools boost development speed, improve software quality and serviceability, and reduce project costs. We also make IMT DATAFLOW tools available to our clients, enabling them to easily adopt a modular, event-driven approach in their own embedded projects.

Complementing this is IMT Base, our proprietary software library offering modular, reusable, and field-tested components tailored to the demands of medical and high-tech systems. Combined with IMT DATAFLOW, it allows for the rapid creation of embedded software that meets stringent industry standards while supporting long-term maintainability.

Our expertise continues to evolve. In 2024, we expanded our capabilities to include Zephyr RTOS for real-time, low-power applications and Linux Yocto for scalable embedded Linux solutions.

Whether developing high-performance systems or regulatory-compliant medical devices, IMT enables clients to innovate faster, safer, and smarter — with embedded software that’s built to scale and ready for the future.

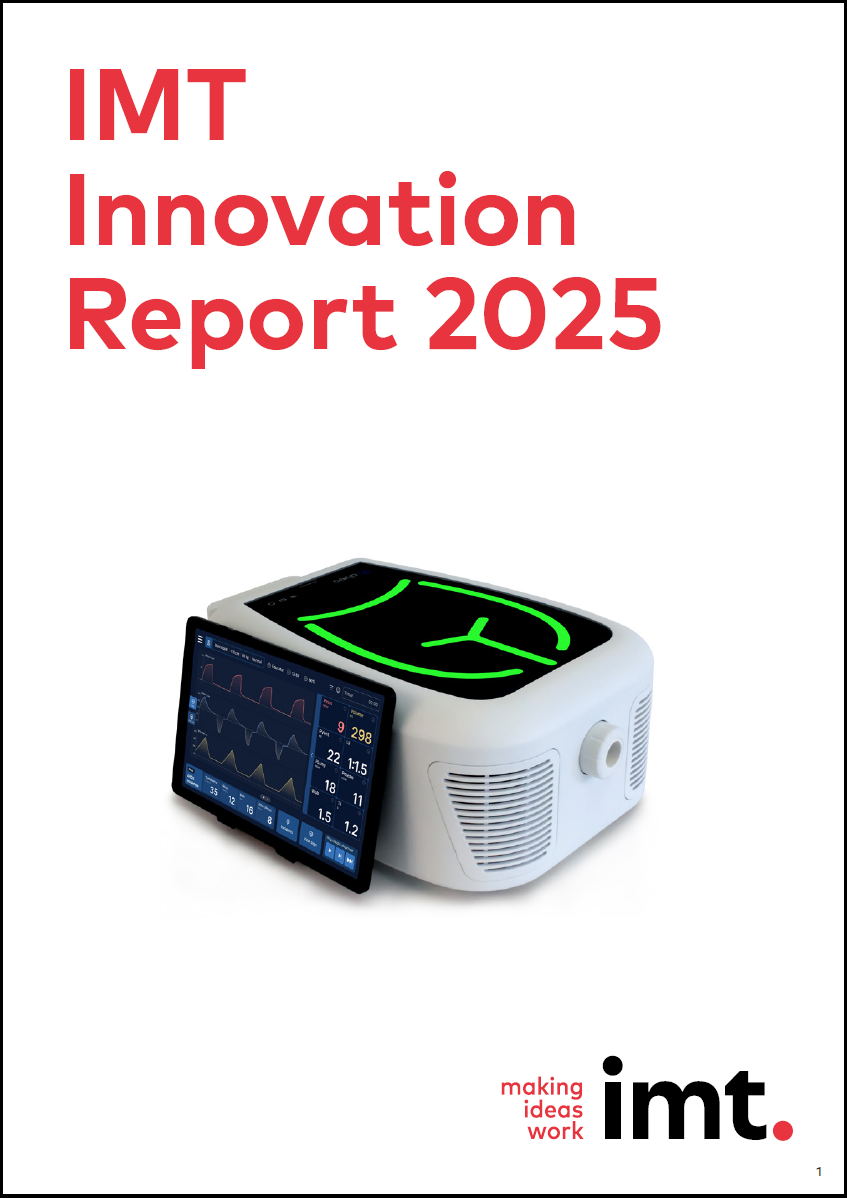

Innovative Lung Simulator

Innovation at IMT goes beyond enhancing existing solutions — it's about pioneering advancements the world has never seen before. In the past, we brought to market the innovative patient ventilator under the bellavista brand. In 2025, we will launch another milestone: the alveo lung simulator.

Developed for our sister company IMT Analytics, alveo is an advanced, high-fidelity lung simulator designed to transform respiratory training, ventilator development, and clinical research. Technologies featured earlier in this report — such as rapid prototyping, simulation, and generative design — play a key role in alveo’s development, enabling innovation in form, function, and performance.

A defining innovation of alveo is its use of turbines to simulate lung resistance and compliance, setting it apart from conventional simulators. Unconstrained by tidal volume, alveo supports a wide range of use cases — from neonatal to adult, and even large animal simulations. Its adaptive operating modes (passive, spontaneous, and hybrid breathing) offer unmatched flexibility.

alveo is further equipped with a physiological feedback model that simulates an entire patient including the impact of the ventilation on the circulation and blood gas paramters. A built-in condition library allows users to simulate normal, restrictive, or obstructive lung scenarios, while adjustable leakage settings add precision for ventilator testing and training.

With wireless connectivity, a user-friendly interface, and a compact design, alveo meets the rigorous demands of modern simulation and R&D environments. By driving innovations like alveo, IMT continues to push technological boundaries — delivering marketready solutions that improve lives and advance the medtech industry.

IMT Academy

At IMT, we believe that enabling innovation in our customers and the broader MedTech community begins with sharing knowledge. That’s why we created the IMT Academy — a platform to pass on the insights and expertise we’ve gained from over 500 customer projects delivered across more than 30 years in medical technology development.

Our IMT Academy offers practical, high-impact training designed to strengthen teams and accelerate development processes. Our courses and webinars are grounded in real-world experience and tailored to the needs of engineers, quality managers, and innovators in the MedTech field.

We cover a wide range of topics, including:

- Fundamentals of Medical Device Development

- Design Thinking & Usability

- Specification, Verification & Validation

- Technical Documentation for Medical Devices in Europe

- Standards for Medical Electrical Equipment

- Market entrance for medical device manufacturers in Switzerland and USA

We offer:

- Regular half-day or full-day courses

- Expert webinars on current trends and challenges

- Fully customized training programs, tailored to client-specific projects, technologies, and goals

One of the Academy’s greatest strengths is its flexibility.

Courses can be delivered on-site at IMT, online, or directly at the customer’s location, ensuring convenience and maximum learning impact. Whether it’s navigating regulatory approval, improving usability, or deepening understanding of cybersecurity or V&V, our seasoned experts bring clarity through structured content, real examples, and hands-on insight.

With IMT Academy, we’re not just delivering training — we’re building the foundation for the next generation of MedTech innovation.

IMT Services

IMT is a Swiss engineering company that turns customer visions into reality in medical technology and industrial applications. We support development projects from idea to registration, guiding clients through design, prototyping, engineering compliance, and transfer to manufacturing for seamless product realization and a fast time-to-market.

Product Concept

- Innovation Workshops

- Industrial Design

- UX & UI Design

- Feasibility Studies

- Usability Studies

Product Development

- Rapid Prototyping

- FE & CFD Simulations

- Electronics Design

- Embedded Software

- Controls & Signal Processing

Regulatory Consulting

- Technical File

- Verification Testing

- MDR- & FDA-Submission

- Market Surveillance

- QMS Consulting

Lifecycle Services

- Lifecycle Analysis

- Sustaining Engineering, EoL

- Design to Cost

- Design for Manufacturability

- Test Equipment

Ready to Innovate?

Kickstart your next project with our exclusive Requirements Workshop!

- Define goals & requirements for a clear project vision

- Explore technologies & solutions with IMT experts

- Get a tailored development plan with costs & milestones

On-site, online, or at your preferred location.

Secure your workshop today and set your project up for success or contact us and find out how we can support in making your ideas work!

More Expert Blog articles

Discover IMT’s engineering expertise and innovative solutions in our Expert Blog. Gain valuable know-how from our experts and explore technology highlights.