Re-Engineering of Automotive Components

Re-Engineering of Automotive Components – Rethinking Spare Parts

Modernization through digitization – when spare parts are no longer available

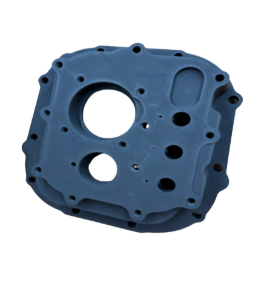

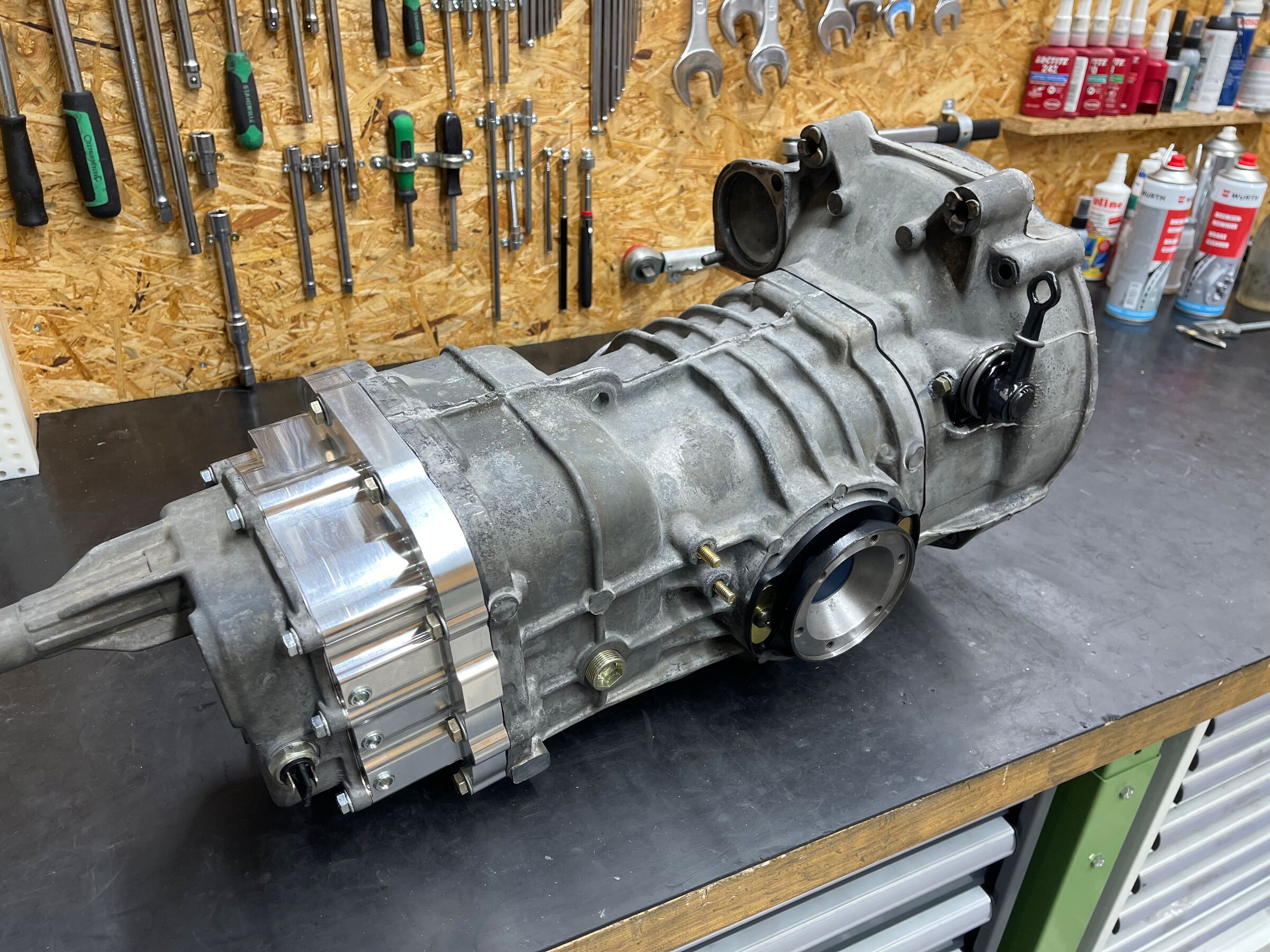

Many older technical devices and machines remain in use, even though spare parts are difficult or impossible to obtain. This was the situation faced by dw-motion GmbH, which required specific transmission components for VW classic cars – without access to drawings or new parts.

IMT took on the challenge of fully digitizing the component using a CT scan, supplementary measurement data, and the original part, then redesigning and optimizing it for manufacturing. A key success factor was the close collaboration with the client and production partner SEPO AG in Bad Ragaz. SEPO is a long-standing partner of IMT, known for its high quality, reliability, and international competitiveness – enabled by a high degree of automation.

Fact Box – Project Overview

|

Project type |

Reverse Engineering of Automotive Components |

|

Project duration |

3 month (each Components) |

|

Technologies Used |

CT-Scan, CAD Modeling, FDM 3D Printing |

|

Component |

VW Transmission Part |

|

Client |

|

|

Production partner |

|

|

Benefits |

Fast, precise, customized |

Technical Implementation

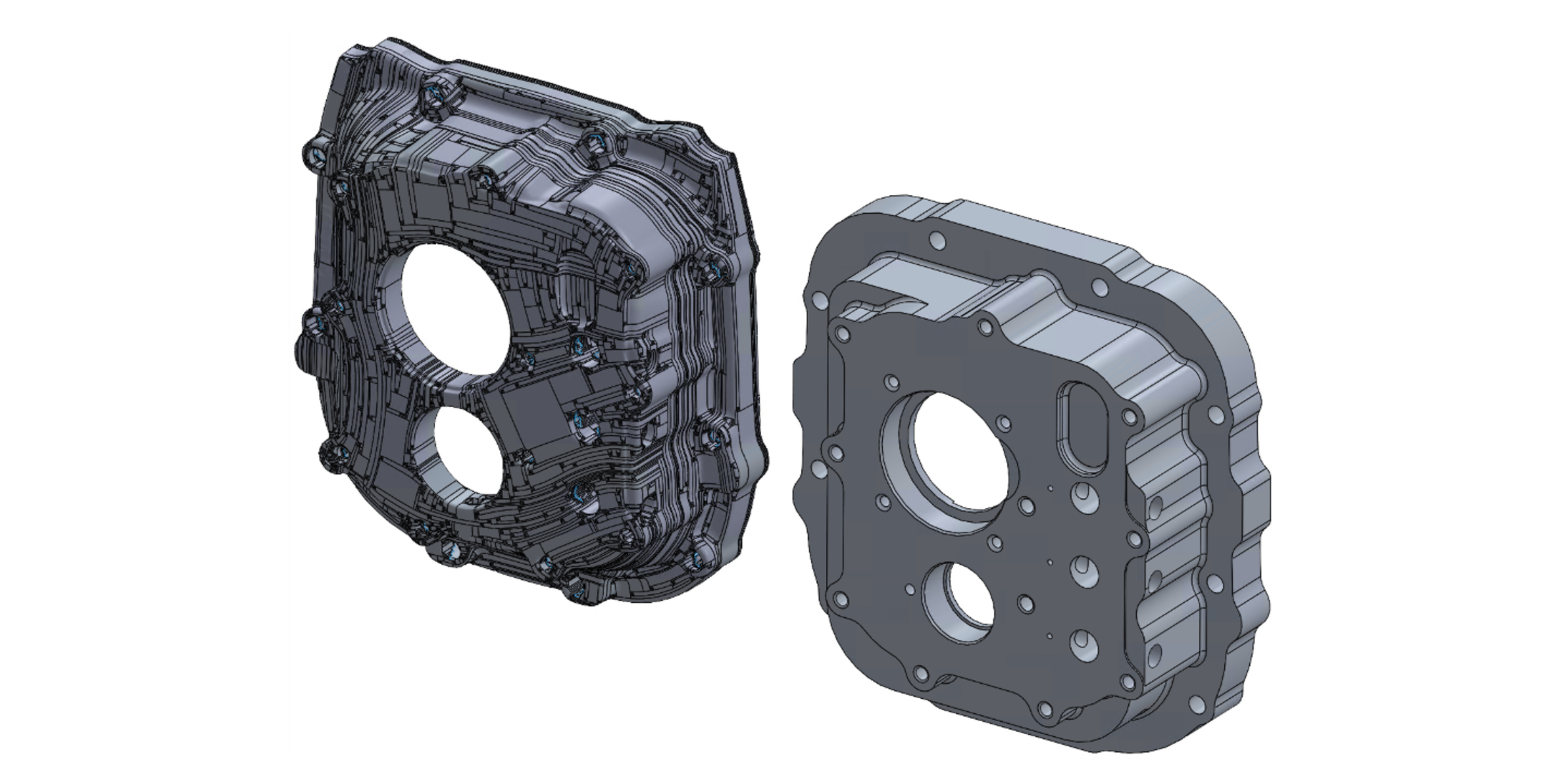

From CT scan to digital model

Dw-motion provided used and NOS (New Old Stock) original parts, a 3D CT scan, and a measurement report.

The CT scan served as a volumetric reference for creating an initial 3D geometry in the CAD tool SolidWorks. Since CT models typically consist of polygon meshes with many individual surfaces, the measurement report was used for precise validation of geometry and tolerances.

Design, Optimization, and Validation

Following the initial reconstruction, a first alignment with the client took place. Their specific functional requirements were directly incorporated into the model.

The new component was also optimized for later CNC machining in close collaboration with SEPO AG – a crucial step for cost-effective production. IMT’s expertise in material- and manufacturing-oriented design complemented SEPO’s process know-how perfectly.

3D Prototype for Fast Validation

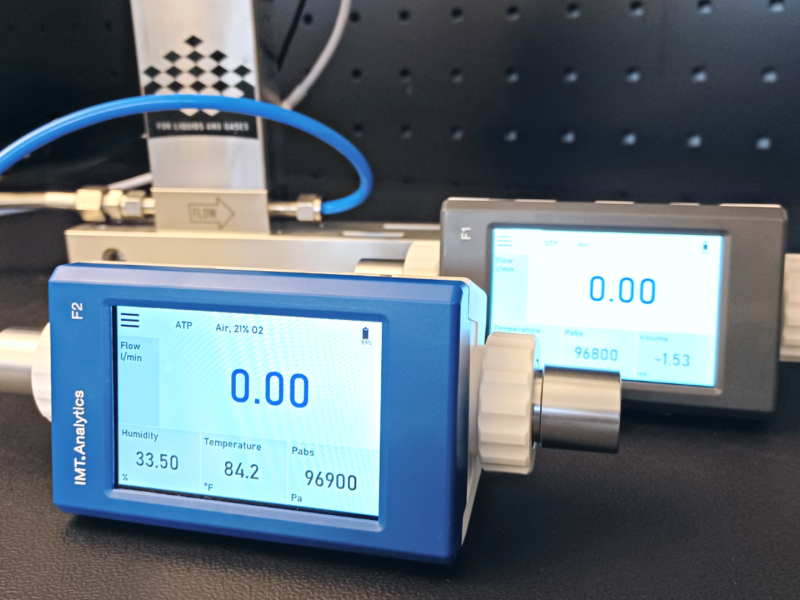

To verify fit and functionality, a prototype was created using FDM 3D printing.

This additive manufacturing method enabled fast and cost-effective iteration. With simple post-processing steps – such as thread cutting or reaming – the part could be installed and functionally tested directly.

Finalization and Handover

In parallel with validation, production-relevant drawings were created and toleranced in close coordination with dw-motion and SEPO AG.

After successful functional testing, the final release of the production documents (3D model + technical drawings) was issued.

Customer assembles prototypes in the experimental setup

(prototypes)

Summary

Reverse engineering reimagined – efficient, precise, flexible

This project demonstrates how modern technologies such as CT scanning, CAD modeling, and 3D printing can be used to recreate even hard-to-source spare parts.

The combination of digital and analog data sources enabled precise reconstruction – enhanced with custom optimizations for functionality and manufacturing.

Benefits at a glance:

- CT scan as reference for complex geometries

- Combined validation using original part and measurement report

- Early functional testing via cost-efficient FDM prototype

- Integration of customer-specific requirements during design

- Direct communication between client, designer, and manufacturer

- Accelerated transition to series production

Thanks to short communication paths and a broad range of in-house expertise, IMT was able to deliver tangible value to the client in a short time – true to the motto: making ideas work.

“For our services in the classic car sector, high-quality and available spare parts are essential. Through our collaboration with IMT, we were able to ensure exactly that: professionally developed products, a reliable supply chain, and maximum customer satisfaction. Our clients appreciate the quality and precision of the components – they are a key contribution to preserving the long-term value of classic vehicles.” – Didi Wildhaber, dw-motion gmbh

“Small production runs with demanding requirements are of interest to us as well. Thanks to IMT’s expert digitalisation of the component, we are able to manufacture a complex part through efficient process steps while maintaining consistently high quality. I valued the straightforward and direct communication with IMT and dw-motion GmbH, and together we were able to produce everything from the prototype to the small series in record time.

And of course, all of it is fully automated within our unmanned night-time production.”- Oliver Oberdanner, SEPO AG